Via della Libertà21 - 10095 Grugliasco (To)

Tel. +39 011 7808118 - fax +39 011 7800518

www.kleentek.it - cgdm@kleentek.it

|

GUIDE TO CORRECT SIZES

|

|||||||||

|

Max. oil quantity (litres) |

Specifications |

||||||||

|

|

Oil viscosity ISO VG |

||||||||

|

Unit |

32 |

46 |

68 |

100 |

Power |

Size |

Weight |

Flow rate |

Collector Type |

|

ELC - R 100 TP |

48.000 |

33.000 |

22.000 |

12.000 |

600 W |

530x1066x1080 |

161 |

12 |

2/CC-R50SP |

|

ELC - R 50 TP |

24.000 |

16.000 |

11.000 |

6.000 |

500 W |

530x725x1080 |

108 |

9 |

1/CC-R50SP |

|

ELC - R 25 TP |

12.000 |

8.000 |

5.500 |

3.000 |

150 W |

350x675x950 |

72 |

3.7 |

1/CC-R25SP |

|

ELC - R 10 SP |

5.000 |

3.400 |

2.200 |

1.200 |

150 W |

350x675x915 |

70 |

2.2 |

1/CC-R10SP |

| ELC - R 3P SP | 800 | 550 | 380 | 150 W | 361x311x531 | 20 | 1.2 | 1/CC-R3SP | |

Available on request are ELC - R150 SP and ELC - R200 SP modular units with multiple capacities of the ELC - R50 SP unit to meet the broadest possible range of requirements. On request: special units for synthetic fluids. Standard power supply ratings: 220 V single phase/380 V three-phase. |

Operating conditions |

||||||||

For oils with temperatures steadily higher than 60 °C (e.g., turbine oils) special "H" cleaners for high temperatures are supplied |

|||||||||

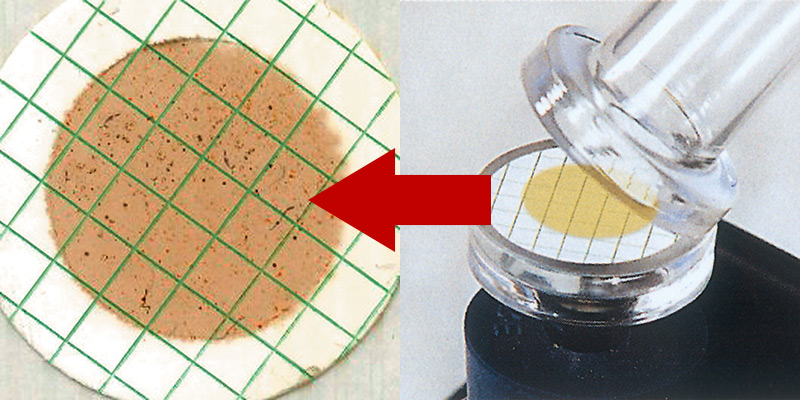

The “KLEENTEK Contaminant Checker” enables you to monitor the workings of the electrostatic cleaner and determine the oil contamination level at any time.

The “KLEENTEK Contaminant Checker” enables you to monitor the workings of the electrostatic cleaner and determine the oil contamination level at any time.

The majority of contamination in a used oil is <1 micron

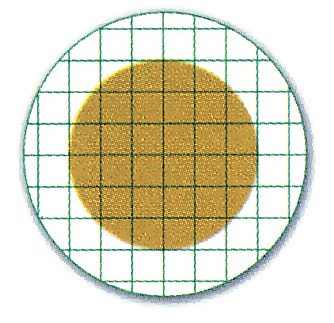

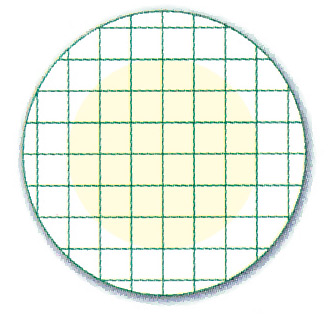

By using the Contaminant Checker KLEENTEK you can find out ALL insoluble contaminants in your oils.

Particle counting does not differentiate between these two samples - however one is much dirtier than the other - this is easily identified by the Contamination Checker Kit. The kit allows you to instantly check your oil, and take immediate action |

|||

| Sample 1 | Sample 2 | ||

| Particle ISO 4406 Counting NAS 1638 |

ISO 4406 NAS 1638 |

15/12 6 |

15/12 6 |

Gravimetric Test |

|

|

|

| Contaminant level mg/100ml |

6 mg/100ml |

<1 mg/100ml |

|

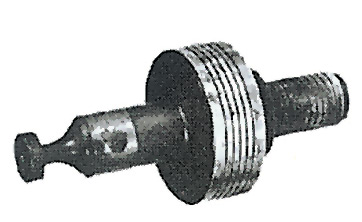

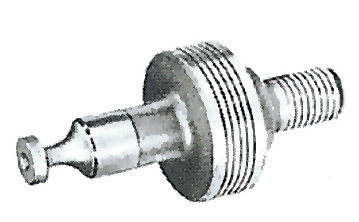

Servo valve from oil system |

|

|

|

• Portable 50x microscope

• Pencil type torch with batteries

• Vacuum pump 240V

• Glass filter holder with funnel & clamp

• 100x0.8 micron (or 0,45 μm) micron filter papers 25mm diam.

• 1 l. bottle of petroleum ether

• Filter paper mounts

• Plastic solven bottle and nozzle

• Plastic bottle for waste fluid

• Graduated glass test tubes

• Plastic sample bottles

• Glass mixing rods

• Tweezers

• Carrying case